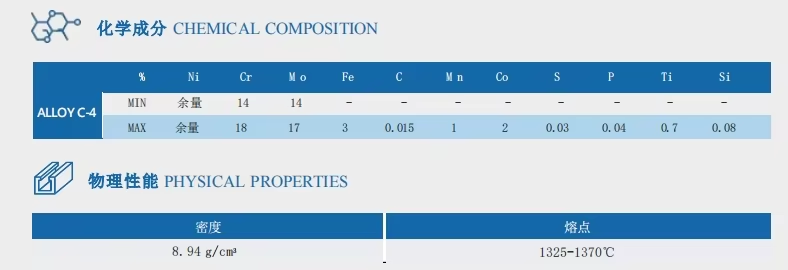

Alloy C-4 is an austenitic nickel-molybdenum-chromium alloy with a

low carbon, silicon, and iron content. This alloy has a

significantly lower tendency to form precipitation in the

temperature range between 650 and 1,040 °C(1,202 - 1,904 °F),

improving its resistance to inter-crystalline corrosion. When

machined perfectly, no knife line attack occurs in the

heat-affected zones of awelding edge. Alloy C-4 is characterized

by: Very good resistance in a broad field of corrosive media, in

particular under strongly oxidizing conditions. Excellent

resistance to pitting, crevice and stress corrosion. The threaded olet is a kind of branch pipe table, which is used

for reinforcing the branch pipe connection. Threaded branch pipe

table is a kind of branch pipe table, which is widely used in

foreign countries in recent years. It is a reinforced pipe fitting

for branch pipe connection. Instead of the traditional reducing

tee, reinforcing plate, strengthening pipe section and other branch

pipe connection types, it has the outstanding advantages of safety

and reliability, reducing cost, simple construction, improving

medium flow path, series standardization, convenient design and

selection. Especially in high pressure, high temperature, large

diameter, thick wall pipe used increasingly widely, replacing the

traditional branch pipe connection method. The body of the threaded

branch pipe is made of high-quality forgings, and the material is

the same as that of the pipe, including carbon steel, alloy steel,

stainless steel, etc. The branch pipe and main pipe are welded, and

the branch pipe table and branch pipe or other pipes (such as short

pipe, wire plug, etc.), instruments, valves are connected by butt

welding, socket welding, thread and other types.

,

,